- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Does a Mechanism Panel Improve Industrial Efficiency?

Abstract: Mechanism Panels play a crucial role in industrial automation, control systems, and energy management. This article explores the technical parameters, applications, and frequently asked questions to help engineers and facility managers optimize operations. It also includes practical guidelines for installation, maintenance, and operational safety.

Table of Contents

- Node 1: Understanding Mechanism Panels

- Node 2: Detailed Specifications and Technical Parameters

- Node 3: Common Questions and Problem-Solving

- Node 4: Industrial Applications and Contact Information

Node 1: Understanding Mechanism Panels

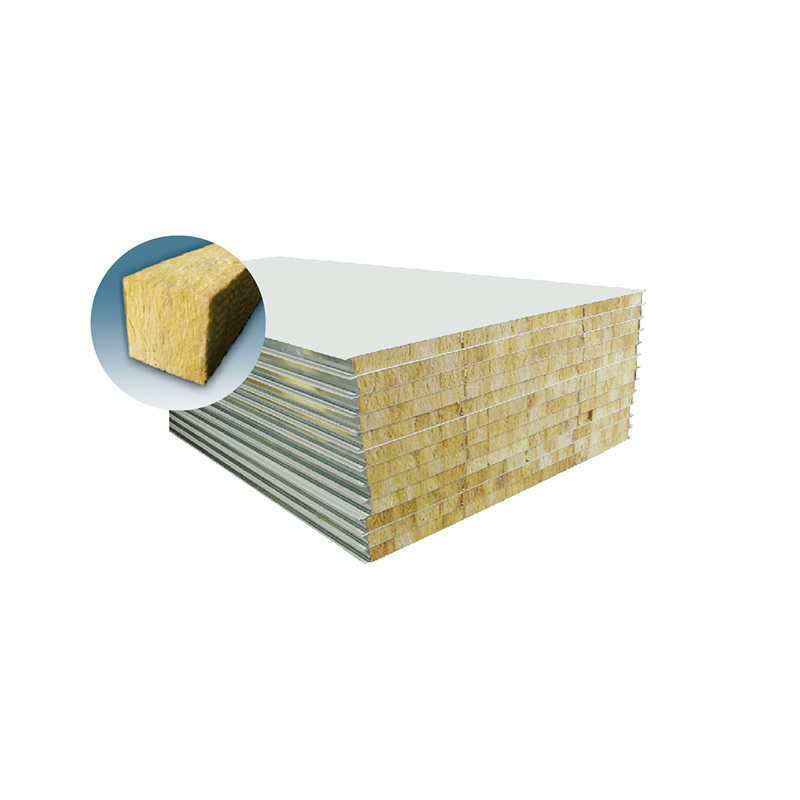

Mechanism Panels are advanced control units designed for industrial environments, providing centralized management of mechanical and electrical systems. They integrate multiple components such as circuit breakers, relays, switches, and automation modules to optimize system performance and ensure safety compliance. The primary purpose of these panels is to facilitate streamlined operations, reduce downtime, and improve monitoring capabilities.

The central focus of this article is to explain how Mechanism Panels function, what technical parameters are critical for decision-making, and how common operational challenges can be addressed efficiently.

Node 2: Detailed Specifications and Technical Parameters

Mechanism Panels are manufactured with high-quality materials to withstand industrial conditions, offering flexibility in installation and scalability for future upgrades. Key parameters include electrical ratings, enclosure protection, and modular design options.

| Parameter | Specification |

|---|---|

| Rated Voltage | 380V / 220V AC |

| Rated Current | 10A - 200A (customizable) |

| Frequency | 50Hz / 60Hz |

| Protection Level | IP54 / IP65 |

| Material | Cold-rolled steel or stainless steel |

| Mounting Type | Wall-mounted or free-standing |

| Control Modules | PLC, relays, timers, and smart automation modules |

| Operating Temperature | -10°C to 60°C |

| Dimensions | Customizable based on system requirements |

These parameters ensure that Mechanism Panels can accommodate complex industrial processes while maintaining safety and reliability.

Node 3: Common Questions and Problem-Solving

FAQ 1: How can the Mechanism Panel be installed safely in an industrial environment?

Answer: Installation requires a qualified technician. Panels should be mounted on a flat, stable surface with sufficient clearance for airflow and maintenance. Proper grounding and adherence to local electrical codes are mandatory to prevent hazards. Protective equipment must be used during installation.

FAQ 2: How to troubleshoot common electrical faults in a Mechanism Panel?

Answer: Begin by inspecting circuit breakers, fuses, and relays for signs of damage or wear. Use a multimeter to verify voltage continuity and check for loose wiring connections. Log all observations and perform a controlled power-up to isolate the faulty component. Preventive maintenance schedules can reduce recurrent faults.

FAQ 3: How can the Mechanism Panel be optimized for energy efficiency?

Answer: Integrating energy monitoring modules and automated load management systems allows real-time tracking of consumption. Adjusting settings to prevent unnecessary idle power usage and ensuring proper sizing of breakers and control units can enhance efficiency. Regular audits and firmware updates are also recommended.

Node 4: Industrial Applications and Contact Information

Mechanism Panels are widely applied in manufacturing facilities, automation lines, energy plants, and large commercial buildings. Their ability to integrate with PLCs, smart sensors, and remote monitoring systems makes them ideal for improving process control, reducing energy waste, and ensuring operational safety.

Industrial users often choose Jinda Mechanism Panels for their reliable performance and customizable solutions. For consultation, installation guidance, or purchasing inquiries, contact us to receive professional support and tailored solutions.